Culinary Croydon: London Transport’s Food Production Centre

Introduction

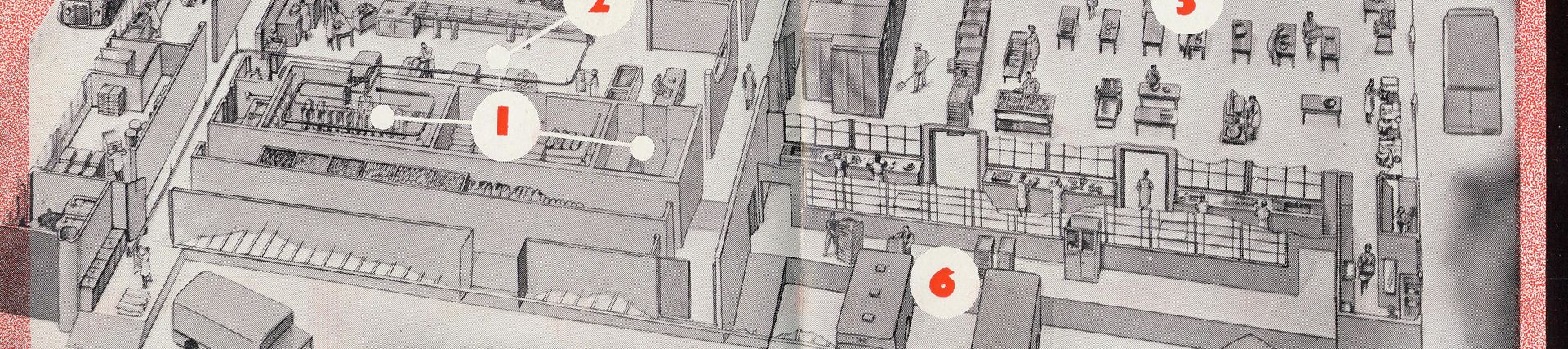

By the early 1950s the catering department of London Transport (LT) operated 165 canteens across the Greater London area, providing meals and refreshments for 74,000 staff. With the catering service struggling to meet demand, a programme of improvements was introduced. At the heart of this was the Croydon Food Production Centre.

Opening in 1950, the Centre aimed to raise the quality of goods used in the canteens. LT could centralise its bulk-buying power. Food could also be prepared and cooked at the Centre for distribution across LT, taking some of the pressure off the canteens.

Mountains of meat

The site – located at Progress Way in Purley near Croydon, then in Surrey – was vast. Staff amenities included a canteen, rest room, First Aid room and shower and bath facilities.

A cold room had capacity to store 30,000lbs of meat and 12,000lbs of fish. Food was transported to and from the loading bay via overhead rails. The butchery and kitchen prepared some 16,000 lbs of jointed meats, 2,000 lbs of cooked meats and 5,000 lbs of sausages every week. A sorting house prepared all the fresh fruit and vegetables destined for the canteens.

Throughout the day, a constant stream of green LT lorries made supply runs to 185 canteens. Others arrived loaded with supplies from the vegetable, fruit and meat markets, such as Covent Garden market (now the home of London Transport Museum). Provisions were sourced from all over the world. The loading bay could simultaneously load eight specially fitted vans. On a weekly basis, the Centre received and issued more than £8,000 worth of stock.

The bakery

As well as providing canteens with produce to be cooked, the Centre also had its own bakery. Fitted with the latest equipment, it was run by a Bakery Manager, two supervisors and 48 members of staff.

Machines played an important part on the production line. They ranged from an electronic eye, which detected foreign objects among dried fruit, to a row of stamping and filling machines. The machines could produce as many as 1,200 tarts or pies in an hour! All of this helped produce over 120 different lines including pies, pastries, cakes and rolls from scratch.

‘Buy Croydon products’

The Croydon Centre’s policy was to provide goods of the highest quality at the cheapest possible price.

Throughout the year, special seasonal items were also produced in vast numbers. A leaflet produced by London Transport in 1966 recorded that the Centre made 100,000 hot cross buns, 45,000 Christmas puddings, 15,000 Christmas cakes and over 1,000 made to order cakes. The bakers took particular pride in iced cakes that were made to order for birthdays, weddings, presentations and other celebrations.

The Centre also contributed to a staff hamper scheme, which was available to all employees. ‘The Christmas Hamper Club’ was publicised in staff magazines as early as the 1930s. Payment could be spread over a period of 48 weeks, starting in January and finishing the first week of December. A choice of different hampers could be ordered directly from the canteens.

Staff could also purchase ‘Home fare’ items by placing an order via the canteens. ‘Special lines’ outside of the normal range of goods, party fare and standard items such as meat, bakery lines and canned goods could all be purchased as advertised in these colourful flyers bearing the griffin logo.

Griffin Tea – ‘the blend with the extra delicious flavour!’

The Centre also produced its own line of food under the ‘Griffin’ brand. Items included chocolate bars, tea, coffee, crisps and sausages.

There was red, blue, green and gold label tea. We then switched to Ashbys as a supplier. These were excellent teas that were really popular in the garages. People who worked for London Transport often bought tea for relatives and friends. It wasn’t unusual to see bus staff taking home crates of tea. The profits that tea produced even offset the cost of providing a quality canteen service.

Response of Brian Staines to a Packet of Griffin Tea, 2008 (UGC record 2008/1842)

The Griffin logo was created for LT by the artist Eric Ravilious in 1936. The logo adorned packaging, crockery and cutlery used by LT catering and remained part of its identity for many years.

Changing tastes

Gradually eating habits in Britain changed. Canteens had to compete with a rise in fast-food outlets, popular catering establishments, take-aways and coffee shops. Ultimately it was the Croydon Centre’s ability to produce a wide range of products that contributed to its downfall. Compared to modern specialised food factories, the Centre had far greater overheads. New legislation also made the sector more challenging.

Inability to meet modern demands

In the early 1980s, LT catering undertook major restructuring. A review of the Croydon Centre estimated that it would cost up to £2m to update and modernise the facility. Plans to introduce a new system for the supply and delivery of goods began.

The Selkent (South East London and Kent) bus district was chosen for a pilot scheme that involved the direct delivery of perishable goods from specialist suppliers. The canteen supervisor became the customer. Supplies could be ordered directly and delivered the next day. The system also provided a greater range of branded goods, enabling the canteens to compete favourably with the local fast food outlets.

End of an era

The Selkent trial proved successful and was eventually rolled out across LT canteens. The inevitable closure of the Croydon Centre began. The bakery, butchery, vegetable preparation and cook-freeze were the first units to close. The last section to leave the building was the catering finance unit in September 1983. Shortly after, the building was demolished and five new blocks containing office and industrial units were put in its place.