The motor bus revolution, 1900 - 1914

Introduction

In 1900 traffic in London was still predominantly hauled by horses – including buses. But horses were expensive to feed and care for, and engineers had been experimenting to find an economic and reliable alternative for many years, with steam and battery power as well as petrol engines.

In 1905 the LGOC owned 7,000 horses, but they would all be gone by the time this photo was taken in 1911.

Although the first motor bus to operate had been in 1899, the early experimental vehicles were not practical or reliable. Progress was slow, but each innovation built upon the last. Sturdier workable buses started to emerge from about 1904, led by the Milnes-Daimler and De Dion companies, used by London’s biggest operators Thomas Tilling and the London General Omnibus Company (LGOC).

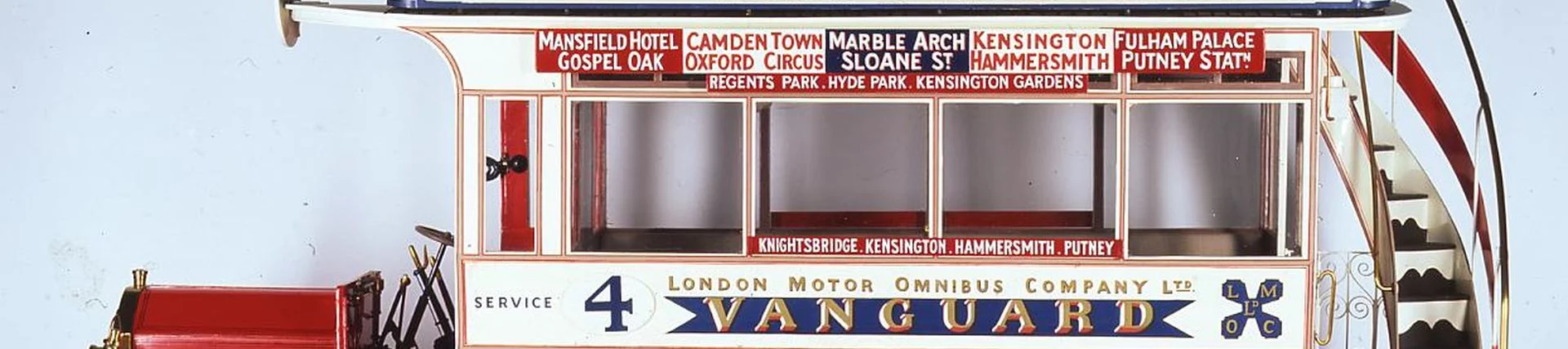

The sharing of routes identified by colour schemes, which had started in the 1840s, continued into the early motor bus period. This started to change in 1905 when the London Motor Omnibus Company adopted the fleet name ‘Vanguard’, painted their vehicles predominantly red and started using numbers to identify routes. When the LGOC took over Vanguard in 1908, they adopted their red livery and route numbering, combining them with its new ‘General’ fleet name and the ‘winged wheel’ symbol. As the LGOC operated the most routes, and continued to buy out their competitors, most of London’s buses turned red in the next year or two.

By 1908 there were 28 different motor bus types running in London, but the LGOC’s chief engineer Frank Searle was not convinced by any single vehicle. The LGOC was now the biggest bus operator in the world, with the resources to design and build its own vehicles. Searle started work on a new bus of his own design, combining features of earlier designs to suit London’s traffic conditions at the ex-Vanguard overhaul works in Walthamstow.

Searle’s new bus, the X type, was unveiled in August 1909. Only sixty were built out of a planned 300, because the X type was soon overtaken by a newer improved model in October 1910, the B type.

The B type was light and sturdy, with an unprecedented top speed of 16 miles per hour. It immediately proved itself on the streets of London. The ex-Walthamstow works became a factory, and before the end of 1910 there were 120 B types on the road. This was followed by another 895 in 1911 and 1,495 in 1912 - the world’s first reliable, mass-produced bus fleet. Electric interior lighting was introduced from 1912, and headlights in 1913. In all, nearly 3,000 B type chassis were built, mostly with bus bodies, but also as lorries and vans.

When the First World War began in 1914, nearly 1,000 B types were commandeered by the War Office, along with many of their drivers. Many were shipped to northern France and Belgium and used to carry troops to the Western Front, some still displaying their London advertisements. Over the next four and a half years of war, these repurposed buses acted as troop transports, ambulances and even mobile pigeon lofts immediately behind the front line. They clearly demonstrated their adaptability and reliability. About a quarter of the total returned to London to carry passengers again after the war ended.